Elastomer In Shear Variety Couplings

The very simple design with the S-Flex coupling assures ease of assembly and trustworthy efficiency. No distinctive tools are necessary for set up or removal. S-Flex couplings is usually used in a wide selection of applications.

Options

Uncomplicated to put in

Upkeep No cost

No Lubrication

Dampens Vibration and Controls Shock

Torsionally Soft

Double Engagement

Qualities and Overall performance Information

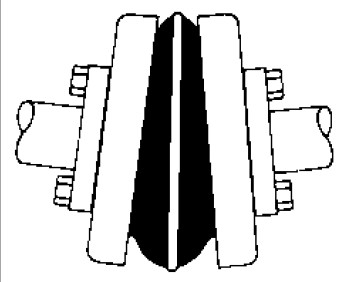

The S-Flex coupling design is comprised of three parts: two flanges with internal teeth engage an elastomeric versatile sleeve with external teeth

Torque is transmited by the flanges mounted on both the driver and driven shafts via the sleeve Misalignment and torsional shock loads are absorbed by shear deflection inside the sleeve

Misalignment and torsional shock loads are absorbed by shear deflection inside the sleeve

The shear characteristic of your S-Flex coupling is quite well suited to absorb affect loads

The S-Flex coupling offers combinations of flanges and sleeves which may be assembled to fit your certain application

Thirteen sizes are available with torque abilities that vary from 60 in-lbs to 72,480 in-lbs

The S-Flex flanges are made available in five versions that are created from zinc or cast iron

Sleeves are available in EPDM rubber, Neoprene to handle a wide range of application prerequisites

Safety from misalignment, shock, and vibration:

PARALLEL:

The S-Flex coupling accepts as much as .062 in of parallel misalignment without the need of wear. The versatile coupling sleeve minimizes the radial loads imposed on gear bearings, a problem commonly linked with parallel misalignment.

AXIAL:

The S-Flex couplings may be used in applications which call for a limited quantity of shaft end-float without transferring thrust loads to equipment bearings. Axial motion of around 1/8 inch accepted.

ANGULAR:

The flexing action of the elastomeric sleeve as well as the locking characteristic of your mating teeth makes it possible for the S-Flex coupling to correctly manage angular misalignment as much as 1??.

TORSIONAL:

S-Flex couplings successfully dampen torsional shock and vibration to protect linked products. The EPDM and Neoprene sleeves have torsional wind-up flexibility of 15?? at their rated torque. Hytrel provides 7??wind-up.